Inspection| Sorting

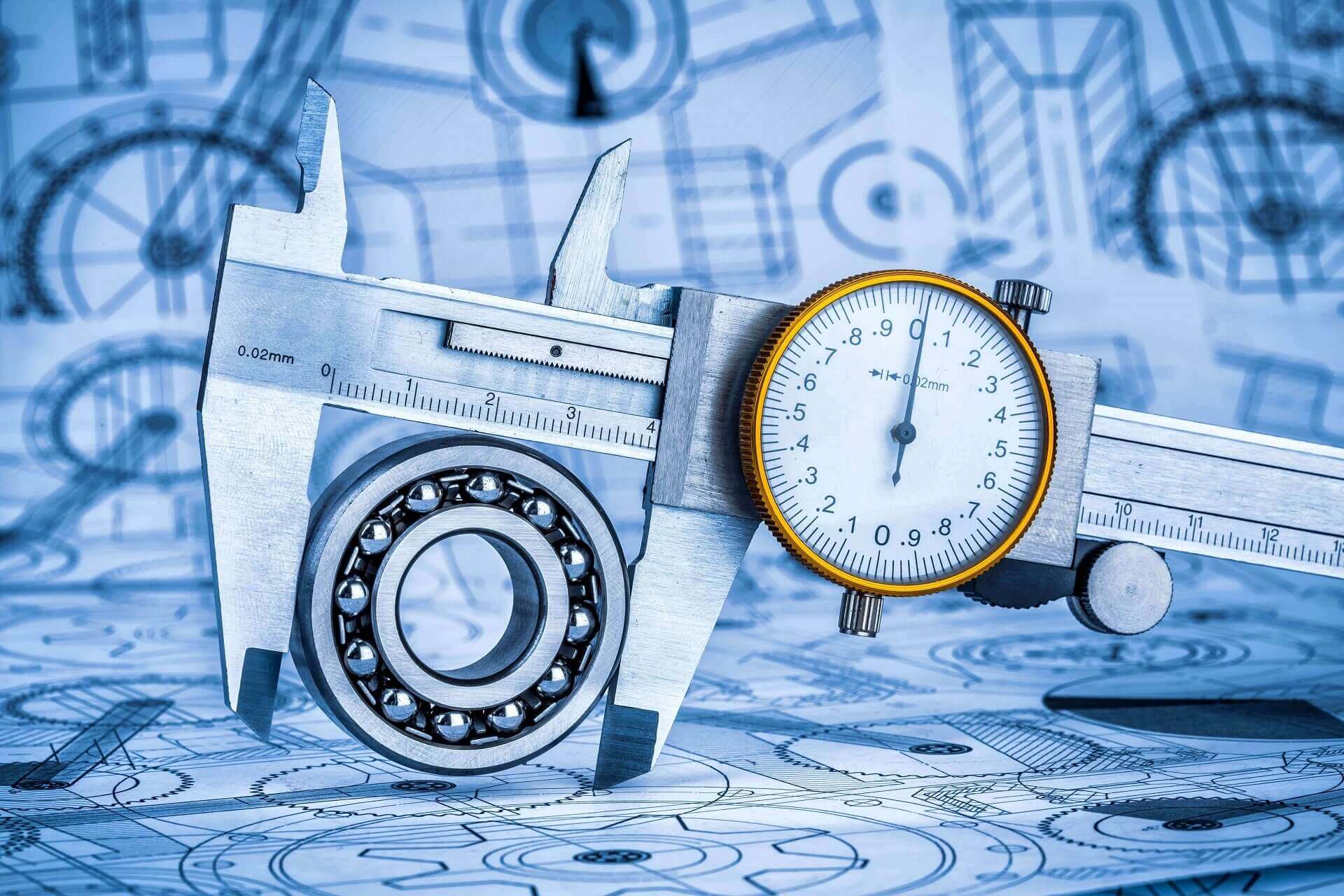

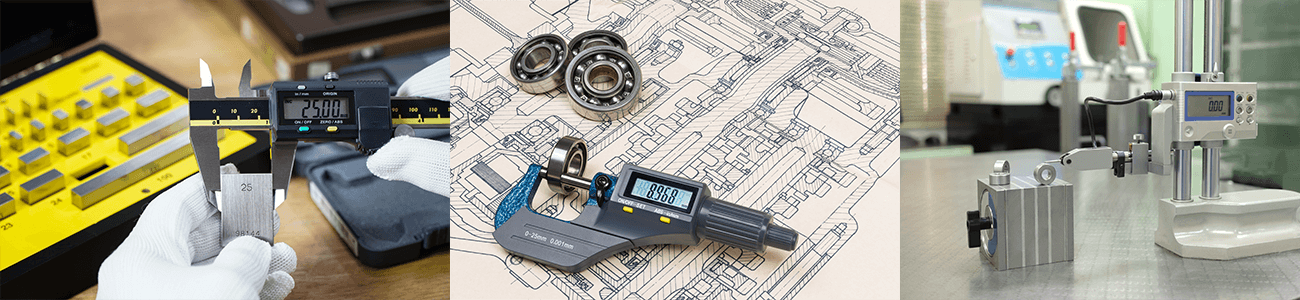

Our quality inspectors are technically trained to use gauges.

Visual Inspection

We perform a visual inspection for your parts to protect you and your customer manufacturing process to ensure everything is in order. Our quality inspectors visually inspect all areas to ensure proper adherence to quality specs.

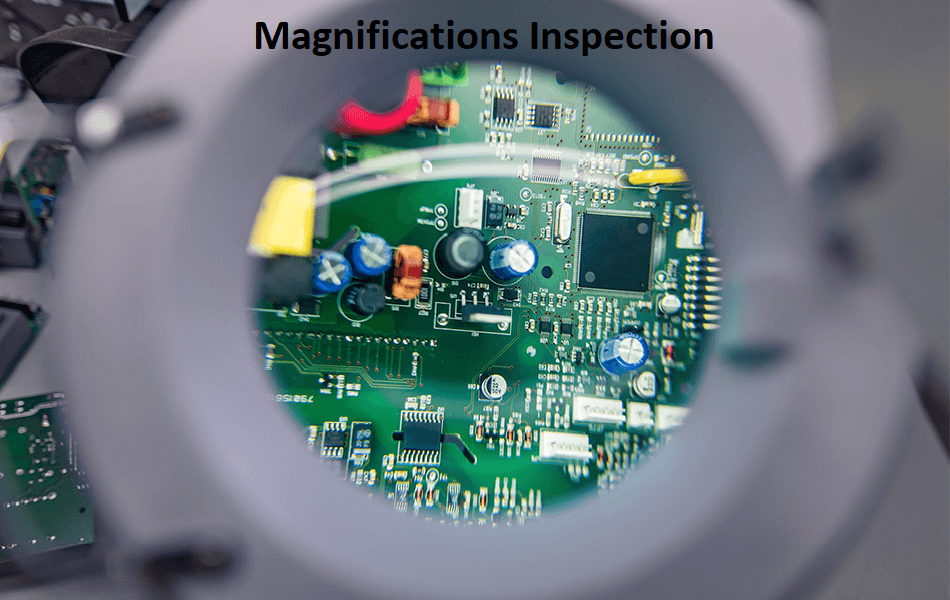

Magnifications Inspection

Our inspection process goes beyond just visual inspection and includes a magnified examination using a specialized device. This device is capable of detecting even the smallest imperfections, such as cracks, dents, burrs, and other flaws.

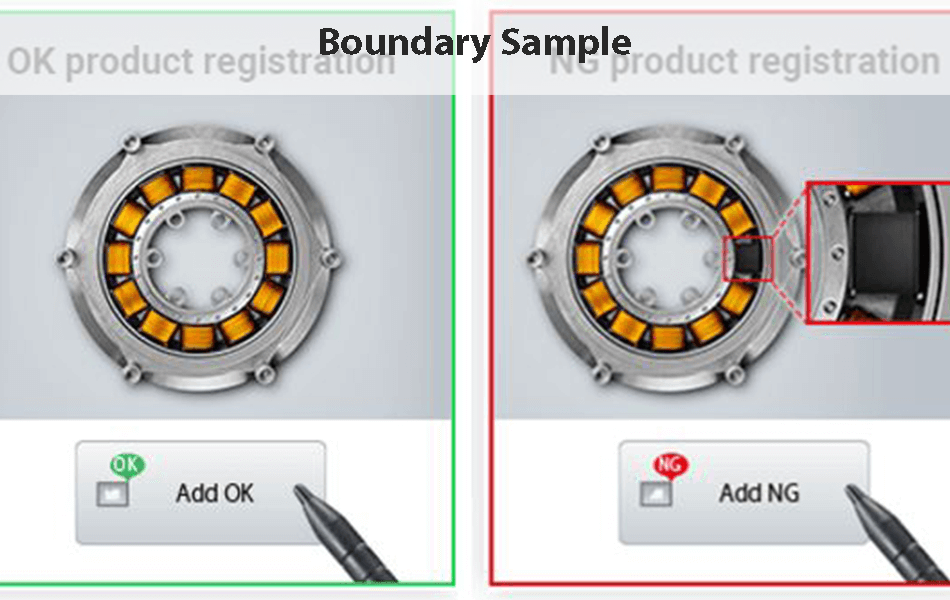

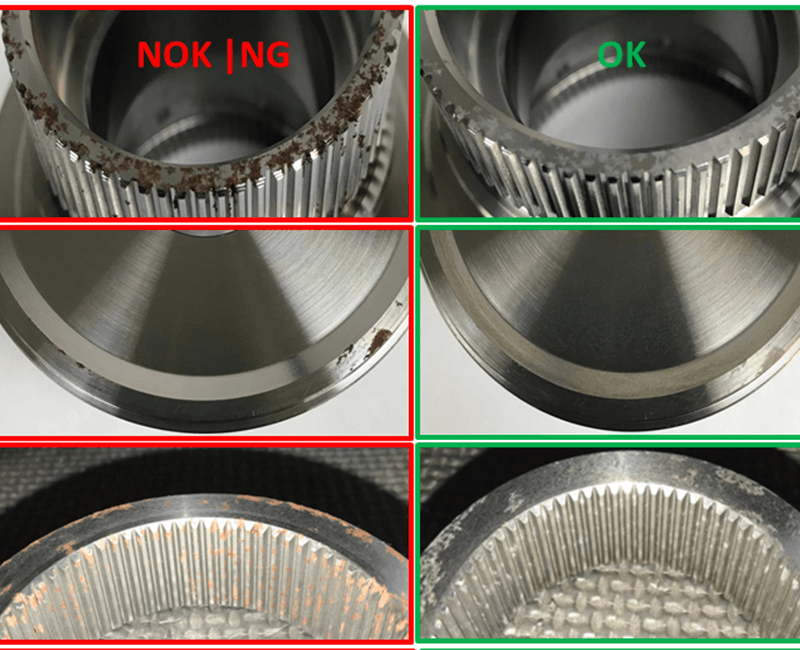

Boundary Sample

Our inspectors are trained to accurately distinguish between acceptable (OK) and unacceptable (NG) parts. To aid in decision-making, they also have a reference sample of the boundaries for identifying NG parts. This ensures that every inspection is thorough and consistent, providing you with reliable results.

Gauge & Torque checks

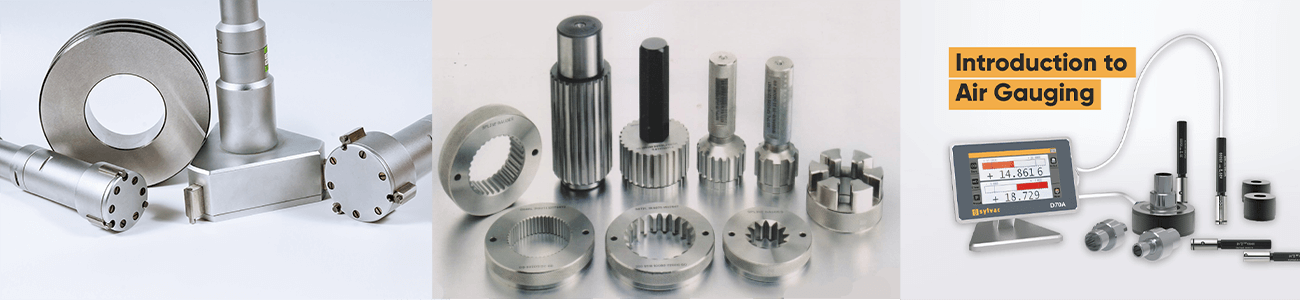

Our quality inspectors are technically trained to use gauges.

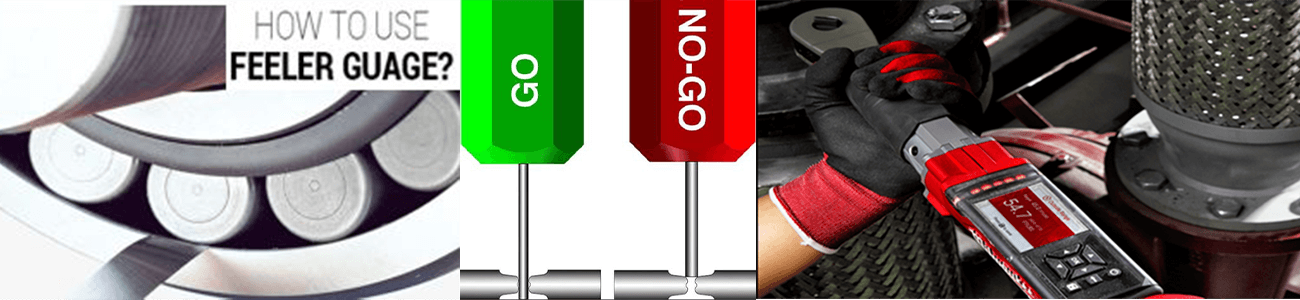

Our team is skilled in utilizing a range of commonly used gauges, including vernier caliper, micrometer, feeler gauge, 3 point bore gauge, height gauge, and air gauge. With these tools, we are able to accurately measure various dimensions such as inner diameter (ID), outer diameter (OD), taper, height, depth, thickness, and gap.

Go | No-Go Gauges: Plug Gauge, Pin Gauge, Ring Gauge [Plain, Thread], Splines Gauge & Snap Gauge.

Torque Verification: Breakaway, Residue & Tighten Torquing.

Other Gauges: In addition to the commonly used gauges, we are equipped to support quality inspections for components using a variety of other gauges. Our highly skilled engineering staff is available 24/7 to design and implement inspection processes that meet your specific requirements.

Artificial Intelligence [AI]

Machine learning

Detection

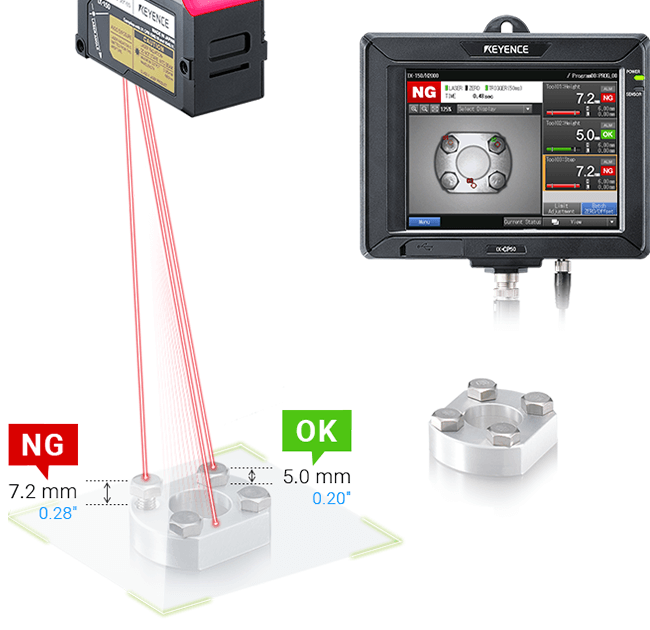

We provide AI-based imaging sensors and vision systems for your projects

We are continuously investing in the latest technology to better serve our customers. We are in the process of acquiring and implementing AI-based detection equipment, which uses sensors and a vision system. This cutting-edge technology is ideal for critical projects and can be easily configured to meet your specific design requirements.

OUR SUPPORT

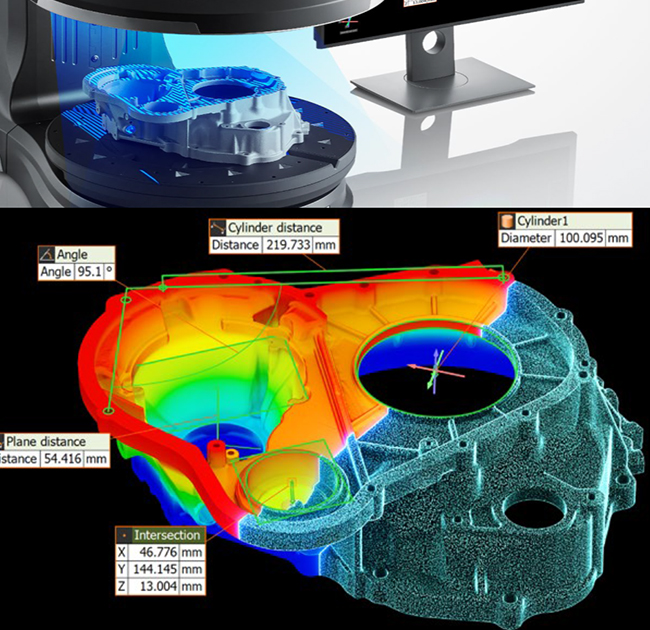

3D Measurement [2 Microns Accuracy]

AI Vision System

Measure majority of GD&T [Ex. flatness, circularity, surface profile, parallelism, ID, OD, height, length etc.]

To check presence of component

To check component fully seated

Color based detection

Endoscope Inspection

We provide endoscope for your projects

Endoscope camera allows for inspection and observation of hard-to-reach areas that cannot be easily seen by the naked eye. Its compact, lightweight design and flexible insertion tube make it easy to carry and maneuver to inspect even the most obscure parts.

Provide Flexibility

Provide Accuracy

Provide Efficiency

Easy to Carry

Reduce the work intensity

Reduce the work intensity

Easy to inspect hidden part

Rework | Repair

We provide the rework solutions for defective parts

We are experts in reworking and repairing parts. Our team is trained to remove rust quickly and efficiently using specialized chemicals.

We also support reworking your assembly to meet torque specifications by 100% torque wrench or digital torque nut runner tool.

We also support reworking your assembly to meet torque specifications by 100% torque wrench or digital torque nut runner tool.

Our team is experienced in replacing non-functioning components and repairing assemblies to bring them back to working order. Let us know if you have any additional rework needs for your projects. We are here to support you.

Containment | CS1 | CS2

You have quality issue? Don’t worry we will contain the suspects components so your customer is protected.

Containment

We understand the importance of maintaining the integrity of your supply chain. That's why we implement a thorough containment process that involves searching for and quarantining any potentially nonconforming product or material. Our aim is to deliver only conforming product, ensuring that your customers receive zero defects.

CS1 - Controlled Shipping Level 1

We are equipped to handle your Controlled Shipping Level 1 (CS1) requirements with ease. Our expert team is ready to provide on-site support to ensure that all CS1 activities run smoothly at your production line. By partnering with us, you can ensure that your production line stays on track and meets all CS1 requirements.

CS 2- Controlled Shipping Level 2

Our team is equipped to handle Controlled Shipping Level 2 (CS2) activities at your warehouse or at customer site. Our focus is to effectively contain any nonconforming products to ensure the delivery of only conforming products to your customers.

New Product Launch

We provide safe launch proactively quality inspection service for new product launch or changes on exiting products to minimize the risk of defective parts sent to your customer.

New Vehicle Launch

We offer comprehensive support for new vehicle launches, covering every stage from start to ramp-up production. Our expert team provides 100% visual inspections for incoming products, as well as in-line and end-of-line inspections to ensure a smooth and successful launch.

New Production Line Launch

For a seamless launch of a new production line, our team can provide an extra layer of inspection support to ensure a smooth transition. Whether you or your supplier are adding a new machine or assembly line, our experts are ready to assist you.

On-site Engineering Support

We offer on-site engineering support for our clients to ensure their manufacturing processes run smoothly and efficiently. Our experienced engineers work closely with clients to address any technical issues and provide expert guidance and solutions.